- Home

- Plastic at Home

- Plastic Recycling Codes

- Chemical Recycling

Chemical Recycling - A Game Changer in Plastic Waste Management

While plastic is everywhere, making our lives easier, its convenience comes at a heavy cost – a growing plastic pollution crisis that threatens our planet.

The need for innovative solutions to manage plastic waste has become more urgent than ever. Traditional recycling methods, while effective to some extent, often fall short in dealing with the complexities of plastic waste streams.

Chemical recycling emerges as a game-changer. This innovative process offers a new approach to address the plastic waste crisis. In this blog post, we'll break down what chemical recycling is, the processes involved, and explore its advantages and disadvantages to give you a well-rounded understanding of this groundbreaking technology.

What is Chemical Recycling?

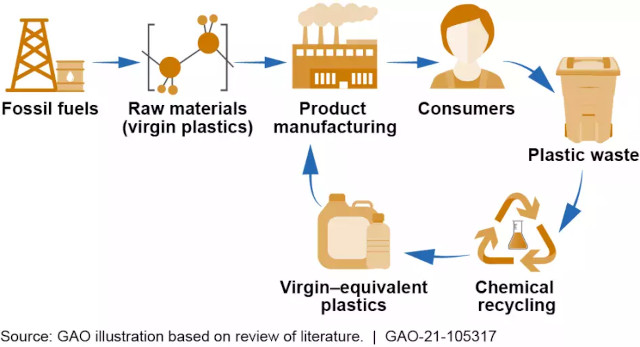

Chemical recycling, also known as advanced recycling, involves breaking down plastic waste into its molecular building blocks, which can then be used to produce new plastics or other valuable materials.

Unlike mechanical recycling, which typically involves melting and reprocessing plastics into lower-grade materials, chemical recycling employs various chemical processes to depolymerize plastics into their original monomers or convert them into useful chemicals and fuels.

Chemical Recycling Processes

Chemical recycling transcends the realm of mechanical sorting and shredding. It delves deeper, breaking down the very molecular structure of plastic waste. Here, we'll dissect four prominent chemical recycling processes. Each of these processes offers unique advantages and challenges, providing diverse options for converting plastic waste into valuable resources.

1. Pyrolysis

Pyrolysis involves heating plastic waste in the absence of oxygen to break it down into smaller molecules, such as gases, liquids, and char. These intermediate products can then be further processed to produce fuels, chemicals, or feedstock for new plastics. Pyrolysis can be conducted using various reactor designs and operating conditions, offering flexibility in terms of feedstock compatibility and product yields.

2. Gasification

Gasification involves converting plastic waste into syngas, a mixture of hydrogen, carbon monoxide, and other gases, through high-temperature reactions in the presence of steam or oxygen. The syngas can then be used as a fuel for power generation or as a feedstock for producing chemicals and fuels through further processing. Gasification offers the advantage of producing a versatile energy carrier from plastic waste while minimizing environmental emissions.

3. Depolymerization

Depolymerization is a process that reverses the polymerization reaction, breaking down polymers into their original monomer units. This can be achieved through various methods depending on the type of plastic and desired end products. The end products of depolymerization are typically monomers or oligomers, which can be purified and used as feedstock for producing new plastics or other value-added materials.

4. Solvolysis

Solvolysis also involves breaking down polymer chains, but it occurs in the presence of a solvent (hence the term "solvolysis"). The solvent interacts with the polymer to facilitate its decomposition into smaller molecules. The choice of solvent depends on factors such as the type of polymer and the desired end products. The end products of solvolysis may include monomers, oligomers, or other decomposition products, depending on the specific conditions of the reaction. These products can be further processed or purified for use in various applications.

Here’s a visual example of how chemical recycling works:

Source: https://www.gao.gov/blog/can-chemical-recycling-reduce-plastic-pollution

Source: https://www.gao.gov/blog/can-chemical-recycling-reduce-plastic-pollutionAdvantages of Chemical Recycling

1. Versatility

Chemical recycling can handle a wide range of plastic types, including mixed or contaminated plastics that are difficult to recycle using traditional methods. This versatility makes it a valuable tool for addressing complex plastic waste streams.

2. High-quality Output

By breaking down plastics into their molecular components, chemical recycling can produce high-quality feedstock for the production of new plastics or other materials. This ensures that the recycled products meet stringent quality standards and can be used in a variety of applications.

3. Closed-loop System

Chemical recycling offers the potential to create a closed-loop system for plastic production, where recycled plastics can be continuously reused without degradation in quality. This reduces the reliance on virgin fossil resources and minimizes the environmental impact of plastic production.

4. Waste Reduction

By diverting plastic waste from landfills and incinerators, chemical recycling helps reduce the environmental burden associated with plastic pollution. It offers a more sustainable alternative to conventional waste management practices, contributing to a circular economy model.

5. Energy Recovery

Some chemical recycling processes can also generate energy from plastic waste by converting it into fuels or other energy-rich products. This can help offset the energy consumption associated with traditional plastic production processes.

Disadvantages of Chemical Recycling

1. Complexity and Cost

Chemical recycling processes can be technically complex and capital-intensive, requiring specialized equipment and expertise. This can make it challenging to scale up and implement on a large scale, particularly in regions with limited resources or infrastructure.

2. Environmental Concerns

While chemical recycling offers environmental benefits compared to landfilling or incineration, some processes may still emit greenhouse gases or produce hazardous by-products. Careful monitoring and mitigation measures are necessary to ensure that the overall environmental impact remains low.

3. Limited Market Penetration

Despite its potential, chemical recycling is still in its infancy compared to mechanical recycling. Limited market penetration and regulatory uncertainties may hinder investment and adoption of chemical recycling technologies in the short term.

4. Feedstock Contamination

Contaminants present in plastic waste streams, such as additives, dyes, or other materials, can complicate chemical recycling processes and affect the quality of the recycled products. Effective sorting and pre-treatment methods are essential to minimize feedstock contamination and maximize recycling efficiency.

5. Competing Technologies

Chemical recycling competes with other waste management technologies, such as mechanical recycling, incineration, and landfilling. The choice between these options depends on various factors, including cost, environmental impact, and technological feasibility.

Chemical recycling holds immense promise as a transformative technology for addressing the plastic waste crisis and advancing the transition to a circular economy. It represents a significant leap forward, but it's not a silver bullet.

We must continue to promote responsible plastic consumption, prioritize waste reduction strategies, and explore innovative solutions like bioplastics. By embracing a multi-pronged approach, we can turn the tide on plastic pollution and create a cleaner, more sustainable future for generations to come.

Reference:

- https://pryme-cleantech.com/chemical-recycling#:~:text=With

- https://resource.co/article/what-chemical-recycling-good-and-bad

- https://glginsights.com/articles/chemical-recycling-types-advantages-and-disadvantages/

- https://wedocs.unep.org/bitstream/handle/20.500.11822/42232/chemical_recycling_sheet.pdf?sequence=3&isAllowed=y

- https://www.rsc.org/globalassets/22-new-perspectives/sustainability/progressive-plastics/explainers/rsc-explainer-6---chemical-recycling.pdf

- https://www.greenmatch.co.uk/blog/chemical-recycling-plastic-waste